IGBT type Static Stabilizers are most suitable for fast, step-less, and accurate Voltage regulation. These systems are built on state-of-the-art technology with dual voltage & current tracking with a robust algorithm to ensure that sensitive loads are effectively protected from grid voltage variations. The basic topology uses a buck-boost transformer with a higher primary secondary ratio for voltage corrections up to +/- 25%. The voltage correction is achieved electronically without any step changes in voltage during regulation. The system is microprocessor-based & works on a feedback & control system.

Need of IGBT Static Stabilizers:

- Increased usage of precision equipment like PLC, CNC machines, AC/DC drives, IT infrastructure etc. These all are very sensitive to input voltage variations.

- Expensive downtimes result in loss of production.

- Voltage fluctuations are affecting the quality of the products, resulting in higher rejection levels.

- Existing constant voltage solutions have very slow response time.

- Moving parts of the voltage corrector affect the load by generating micro sparks & line noises.

- Wear & tear of the moving parts, results in high maintenance cost.

Advantages of IGBT Static Stabilizers:

- Voltage correction through IGBTs with a response time of 100v/msec.

- Fast and accurate continuous correction without overshooting.

- Isolation from line disturbances & fluctuations.

- No moving parts & stepless correction.

- Efficient operation of equipment with increased & qualitative productivity & reduced rejections.

- Compact in size.

- Auto Bypass Facility of the system.

- Output short circuit protection. The AC voltage stabilizer system detects abnormally heavy current flow from input & indicates occurrence of short circuit. Instant tripping will isolate the load & simultaneously switch off the IGBT converter to provide protection against damages.

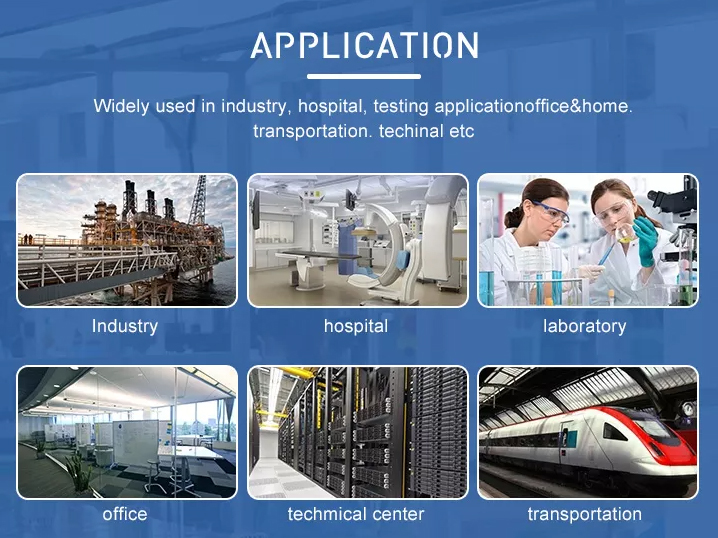

Application Field of Static Voltage Stabilizers

- Medical Equipment, X-Ray Machines, Centrifuge, MRI/CT Scan, etc.

- CNC, Laser & Moulding Machines, etc.

- Printing Machines, Color Processors, Packaging Industries etc.

- Textile & Weaving Industries, Central Air Conditioning, Chemical Industries, Processing Plants, etc.

- Commercial Buildings & Complexes.

- Oil & Gas – Petrol Pumps using dispensing machines centrally connected through SCADA Telecommunications, Radars, etc.

- Information Technology & Call Centres, Defence Installations, IPTs & HPTs